KO1612 | 1.6m*1.2m Flatbed UV Printer

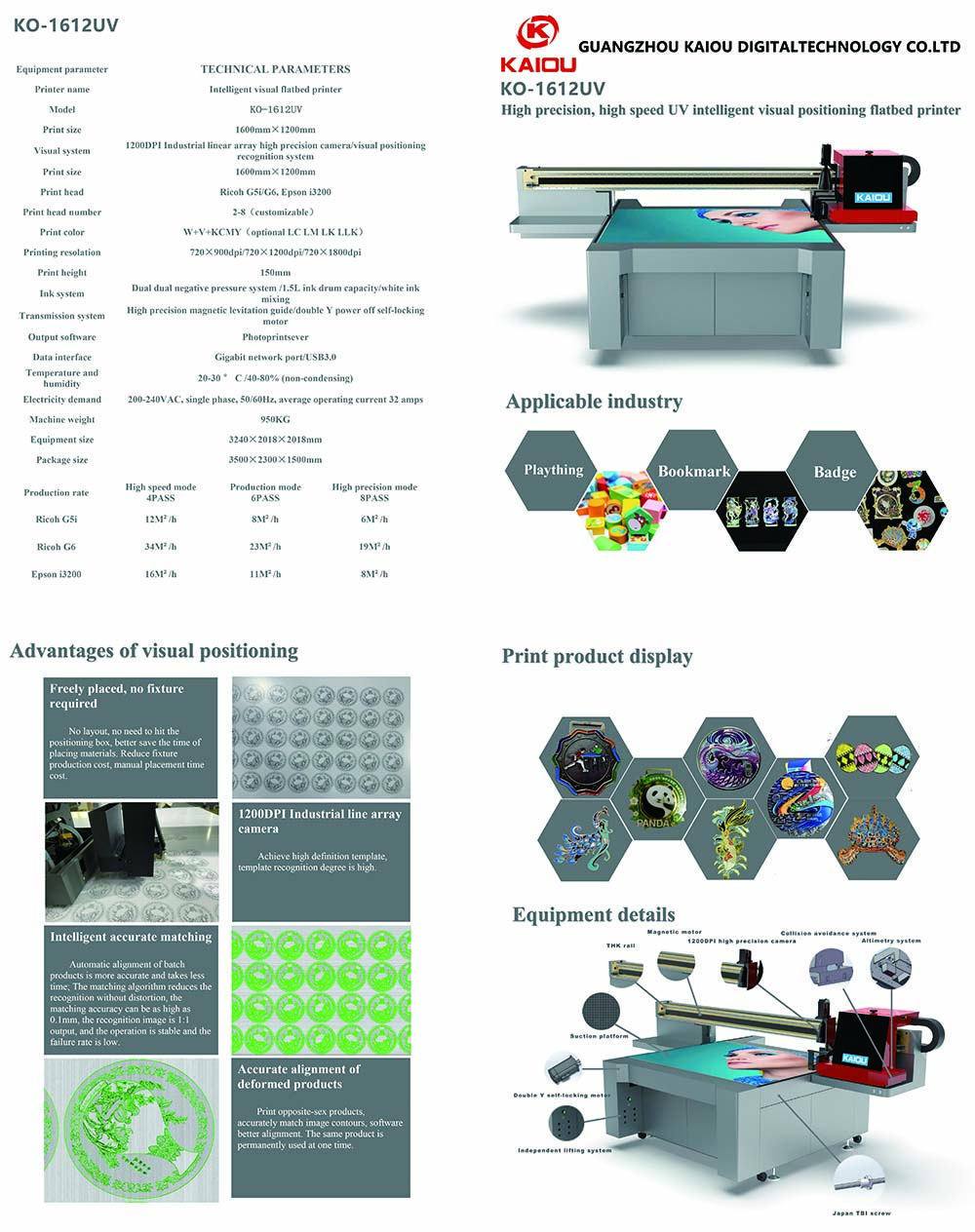

| Model | KO-1612 |

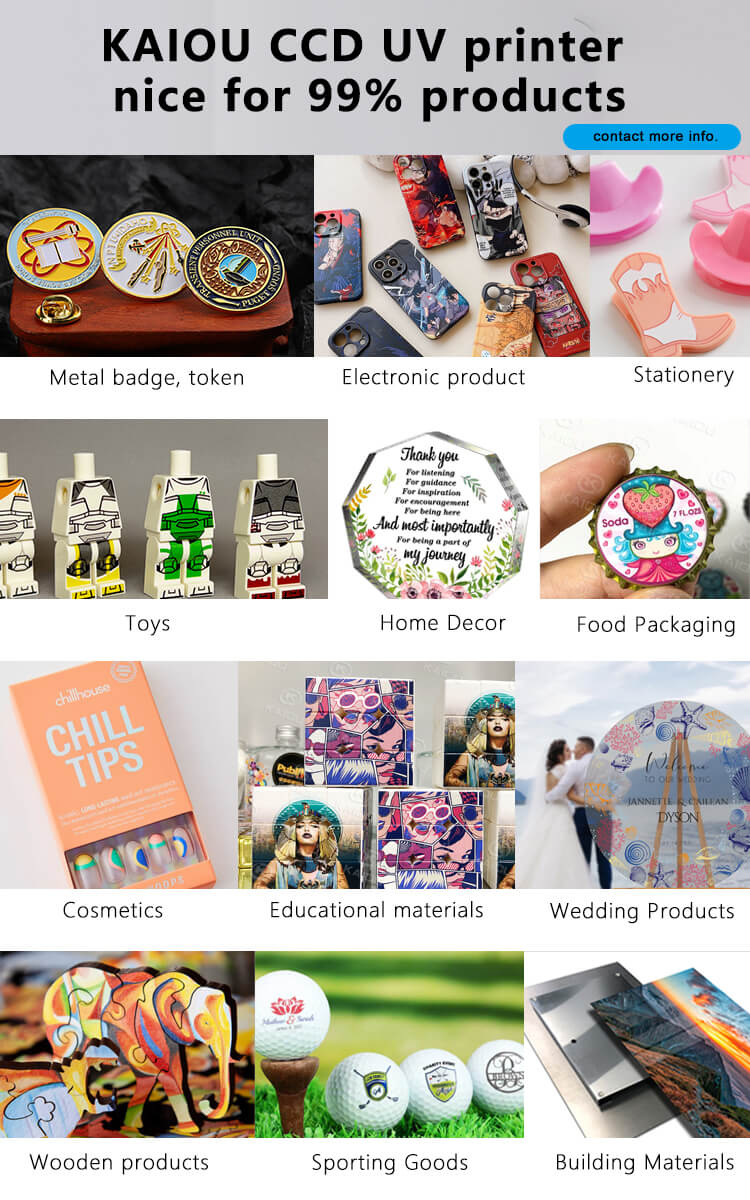

| Application | phone cases, keychains, mugs, badge, token, artwork, decorative panels, custom packaging for luxury items, promotional items, golf ball, pen, USB drivers, Lipstick tubes, cosmetic boxes, toy Rubik's Cubes, leather etc. |

| Printhead | Ricoh G5i/ Toshiba CE4M/ Epson i3200 printhead |

| Print width | 1600*1200mm |

| Print height | 0~100mm |

| Speed | Up to 2000 coins/hour |

| Color | CMYK+W+varnish; support up to 8 colors+varnish |

| Software | RIIN |

| Ink Droplet Size | 3.5PL; 7-21PL |

| Printer size | 320*210*140cm |

| Printer weight | 720kg |

| Package | Wooden |

- Description

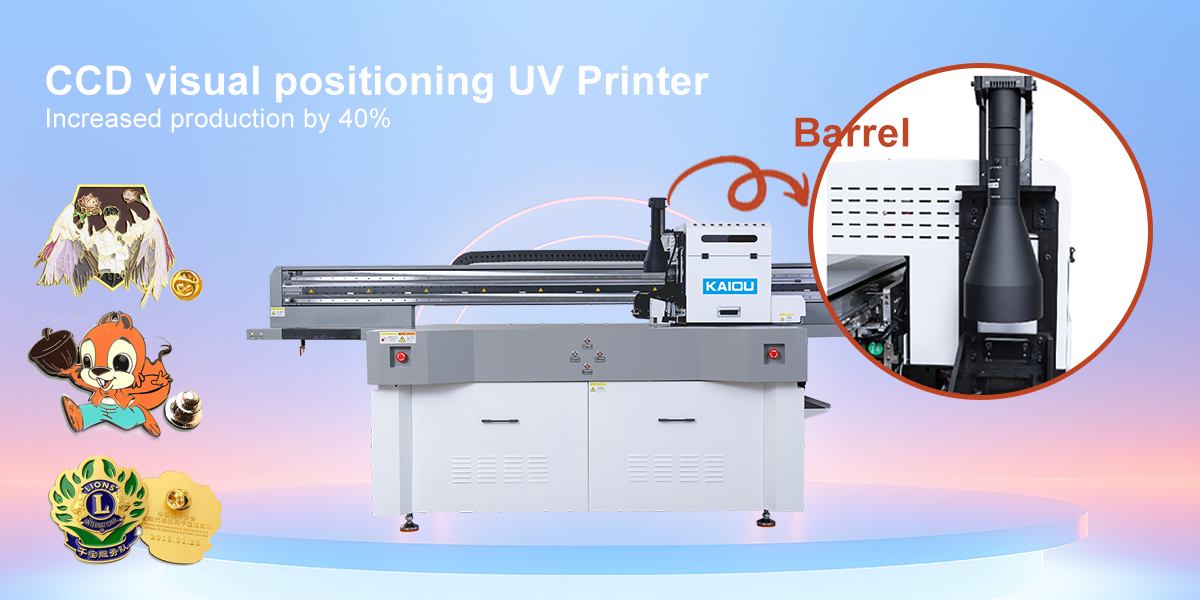

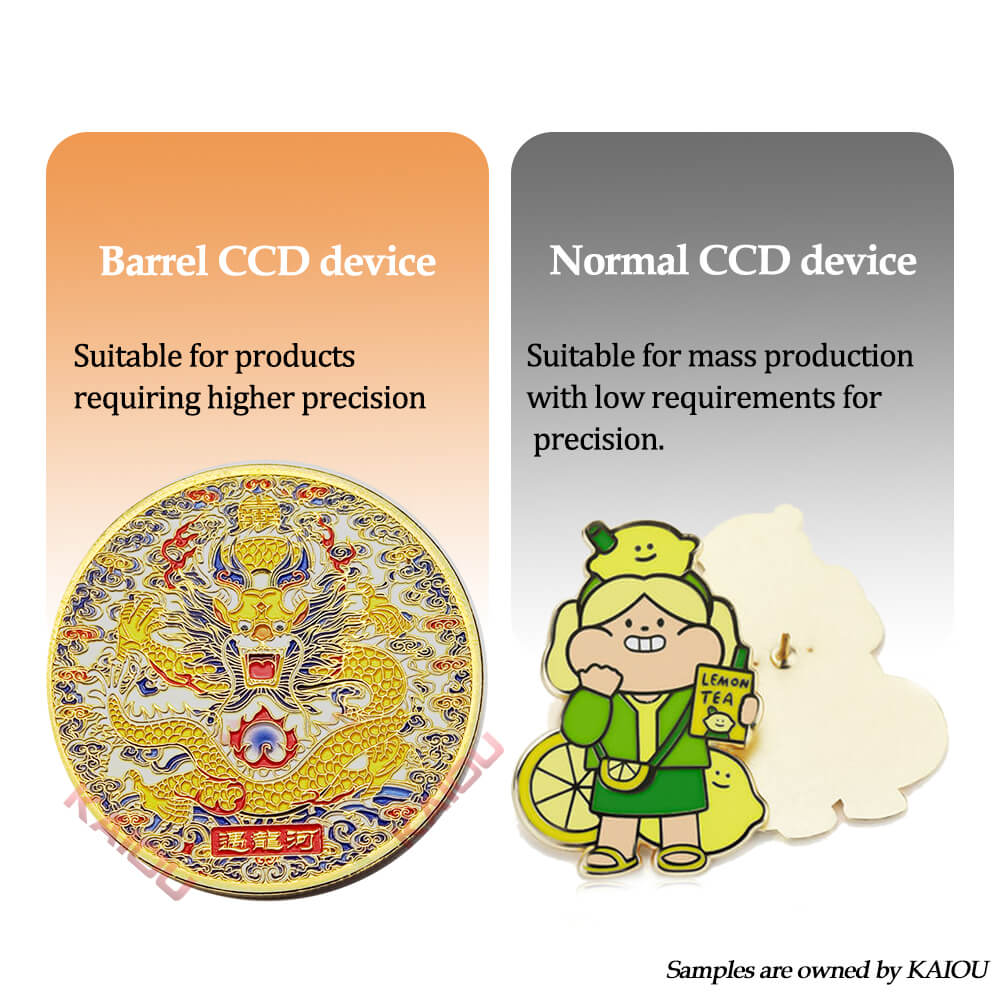

Barrel CCD visual positioning uv printer, Perfect for metal badge!

High definition scanning,Clear and bright colors

KAIOU 1612 UV Printer stands out in the UV printing industry thanks to its cutting-edge visual positioning system. This system sets it apart from standard UV printers, offering precise alignment and enhanced accuracy, particularly useful for industries that require detailed and consistent results. Here's an in-depth comparison between the KAIOU 1612 and typical UV printers, highlighting the printer's features, application processes, and advantages of using KAIOU's proprietary UV ink.

Differences: Visual Positioning UV Printers vs. Traditional UV Printers

KAIOU 1612 UV Printer uses a 1200 DPI industrial linear array camera for high-resolution template recognition. This camera allows precise alignment of even the smallest details. The visual positioning system can automatically detect each product’s position, reducing errors and significantly improving production efficiency.

Traditional UV Printers lack such advanced positioning systems, often requiring manual alignment, which can lead to inaccuracies, particularly when printing on irregular surfaces.

Intelligent Matching:

The KAIOU 1612 can automatically identify and adjust to product contours, even those that are deformed or irregular. It achieves this through its intelligent matching system, which reduces distortions, saving time and reducing errors.

Standard printers, by contrast, typically rely on manual adjustment or require fixtures to maintain alignment, leading to higher labor costs and potential for inaccuracies.

Production Cost Efficiency:

The visual positioning technology of the KAIOU 1612 eliminates the need for expensive fixture production and manual alignment, thereby reducing both material and labor costs.

Without this feature, conventional printers may require more human intervention, increasing labor costs and slowing down production, especially in large-scale operations.

Operation Process of KAIOU 1612 UV Printer

Step 1: Design Preparation The printer supports a variety of file formats such as TTF, BMP, PDF, EPS, and JPG. Users can easily upload their designs using the Photoprint software provided with the printer.

Step 2: Loading the Material Place the material onto the suction platform, which ensures that the object remains in place during the printing process. Thanks to its high-precision magnetic levitation guide rail, the material is positioned securely without the need for clamps or fixtures.

Step 3: Visual Positioning and Alignment Once the material is loaded, the printer’s 1200 DPI industrial camera takes over. It automatically aligns the material according to the pre-loaded template, ensuring every print is consistent and accurate.

Step 4: Printing Process The printer uses Ricoh G5/G6 or Epson i3200 printheads, which are known for their high-speed and precision printing. Depending on the required speed and quality, you can adjust the pass mode (4PASS, 6PASS, or 8PASS) to achieve the desired balance between print speed and detail resolution.

Step 5: Curing and Finishing The printer employs LED UV curing technology, which instantly dries the ink, ensuring the final product is ready for immediate use or further processing. UV-cured prints are highly durable, waterproof, and resistant to fading, making them suitable for both indoor and outdoor applications.

Ricoh G5/G6 and Epson i3200 Printheads:

Both models are known for their reliability, speed, and accuracy. The Ricoh G5/G6 printheads are particularly suitable for high-volume industrial printing, while the Epson i3200 is favored for its versatility in both high-speed and high-resolution tasks.

The printheads allow for variable droplet sizes, which helps achieve smooth gradients and sharp images.

These printheads are compatible with a variety of inks, including KAIOU’s proprietary UV inks.

When choosing between Ricoh G5/G6 and Epson i3200 printheads for your UV printer, several factors come into play, including the type of materials you are printing on, the level of precision you require, your budget, and the volume of printing you plan to do. Here’s a breakdown of the differences and advantages of each:

1. Ricoh G5/G6 Printheads:

Durability: Ricoh printheads, particularly the G5 and G6 models, are known for their robustness and longevity. They can withstand long-term usage in industrial environments without significant degradation, making them suitable for high-volume printing tasks.

Drop Size and Precision: The Ricoh G5/G6 printheads have variable droplet sizes (from 7 picoliters up to 21 picoliters), which allows for precise control over ink placement. This makes them ideal for high-resolution printing tasks where detailed images or fine text are required.

Speed: Ricoh G5/G6 printheads generally offer faster printing speeds compared to Epson i3200. The Ricoh G6, in particular, offers high-speed performance with exceptional accuracy, especially for large-scale printing jobs.

Applications: They are well-suited for industrial uses, such as large-format UV printing on rigid surfaces (wood, glass, metal) or flexible materials, making them ideal for signage, packaging, and advertising.

Cost: Ricoh printheads, especially G6, tend to be more expensive than Epson’s i3200, but they offer greater longevity and a lower total cost of ownership over time due to their durability.

Ink Compatibility: Ricoh printheads are compatible with a wide range of inks, including UV, solvent, and aqueous inks, making them highly versatile for various applications.

2. Epson i3200 Printheads:

Affordability: The Epson i3200 printhead is typically more affordable than Ricoh printheads, making it a great option for small to medium-sized businesses or for those who need an entry-level industrial printer with high-quality output.

Drop Size and Quality: The Epson i3200 printhead offers smaller drop sizes, which means it can produce high-resolution prints (down to 2.5 picoliters), perfect for fine details and color gradients. This makes it ideal for printing applications like cosmetic packaging, electronics, and personalized items where fine details matter.

Speed: While the Epson i3200 is generally slower than Ricoh’s G5/G6, it still delivers solid performance, especially in medium-volume printing environments.

Print Quality: Epson printheads are known for their exceptional color reproduction and image clarity, particularly in applications where photographic-quality prints are required. The i3200 is designed to produce vivid colors and sharp details, making it a popular choice for labels, artwork, and gift customization.

Applications: Epson i3200 is often used in smaller scale production environments, particularly for cosmetics, stationery, and small electronics where print quality and precision are more critical than speed.

Ink Compatibility: The i3200 is generally compatible with water-based inks and UV inks but may not have the same range of ink compatibility as the Ricoh models.

When to Choose Ricoh G5/G6:

If you need high-speed and high-volume printing for industrial purposes.

For durability and long-term usage with minimal maintenance.

If you are printing on rigid materials like glass, wood, or metal.

When cost per print and total cost of ownership are key concerns over the long run.

When to Choose Epson i3200:

If you need high-resolution prints with fine detail (small drop size).

If you are on a budget and need an affordable solution for high-quality prints.

If you are primarily printing on small items like packaging, cosmetics, and electronics.

If color reproduction and vivid details are more important than speed.

If you prioritize speed, durability, and are printing on various substrates in an industrial setting, Ricoh G5/G6 printheads are the better choice. However, if you are looking for high-resolution, affordable printing with excellent color reproduction for smaller-scale applications, the Epson i3200 printhead is an excellent option.

Each has its strengths, and the best choice depends on your specific needs and the scale of your production.

KAIOU UV Ink

Fast Drying: The UV ink dries instantly upon exposure to the printer’s LED curing system, reducing production time and eliminating the risk of smudging.

Durability: UV ink is scratch-resistant, waterproof, and highly resistant to fading, making it ideal for outdoor signage and packaging.

Eco-Friendly: UV inks produce less volatile organic compounds (VOCs) compared to traditional inks, making them a more environmentally friendly option.

Enhanced Vibrancy: The ink's formulation ensures excellent color saturation, producing vibrant and vivid prints on a wide range of materials, including wood, glass, metal, and acrylic.

ROI and Business Benefits

Investing in the KAIOU 1612 UV printer offers long-term value for businesses that require precision printing on diverse materials. Here’s how:

Increased Production Efficiency: The visual positioning system eliminates manual alignment and fixture production, drastically reducing the time required to set up each print job.

Reduced Labor Costs: The automatic positioning system means less human intervention is required, saving businesses on labor costs.

High-Quality Output: With resolutions of up to 1440 dpi and Ricoh/Epson printheads, the KAIOU 1612 ensures each print is vibrant, accurate, and durable, allowing businesses to charge premium prices for their products.

Wide Range of Applications: From billboards to small promotional items, the printer’s ability to handle multiple materials and product sizes makes it a highly versatile investment.

Lower Material Costs: The dual-road negative pressure ink system ensures efficient ink usage, minimizing waste and reducing the overall cost of materials.

For more information on how the KAIOU 1612 UV Printer can transform your business, contact us today for a customized quote tailored to your needs.

English

English  Portuguese

Portuguese  Spanish

Spanish  Hungarian

Hungarian  Indonesian

Indonesian  Italian

Italian  Polish

Polish  Turkish

Turkish  Ukrainian

Ukrainian  Japanese

Japanese  French

French  German

German  Malay

Malay  Swedish

Swedish