Doulble System DTG Printer

| Model NO | DTG-006 |

| Application | Pure cotton or blended fabric with high proportion of cotton |

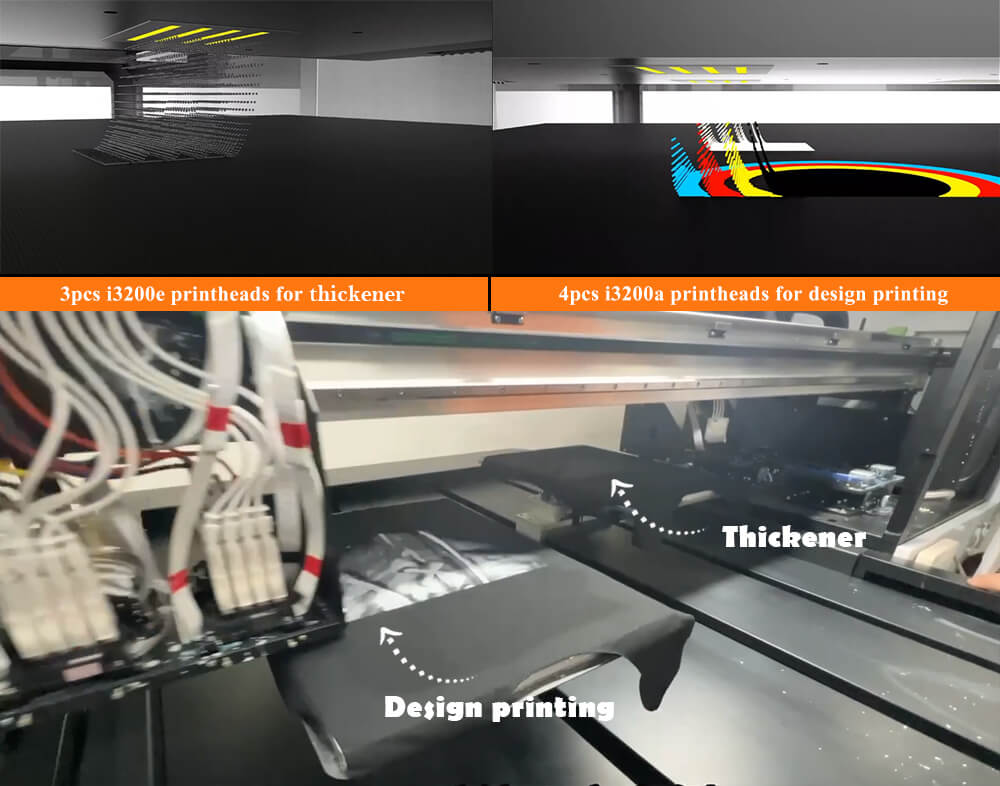

| Print head | Epson i3200*4/13200A1HD*1+13200A1*1; Printhead for Thickener: Epson i3200*2/3 |

| Operating platform | Double station |

| Print size | 41*51CM |

| Printing speed | 100pcs white cloth/hour; 65pcs black cloth/hour |

| Machine size | 1450*2650*2050mm |

| Machine weight | 800kg |

- Description

KAIOU DTG Printer Overview

KAIOU's range of Direct-to-Garment (DTG) printers is designed for high-speed, high-quality printing on fabrics, particularly cotton and cotton-blend materials. These printers are ideal for businesses seeking to produce customized clothing quickly and efficiently. One standout product in this lineup is the KAIOU DTG-006, which features an advanced dual-system capable of streamlining both garment printing and the pre-treatment process. This innovation allows manufacturers to enhance their productivity, reduce costs, and achieve greater consistency in print quality.

What is a DTG Printer?

A Direct-to-Garment (DTG) printer uses inkjet technology to print high-resolution designs directly onto fabric. Unlike traditional screen printing, which requires multiple steps and stencils, DTG printing is efficient for small batches or on-demand orders because it can produce highly detailed prints in a single run. With DTG, you can print full-color images, gradients, and even intricate designs with ease.

In DTG printing, garments—especially cotton fabrics—are fed through the machine, and water-based inks are applied directly to the fibers. A crucial factor in the quality of DTG prints is the pre-treatment process, which ensures that the ink adheres properly to the fabric. This process prepares the fabric surface to receive the ink, ensuring vibrant colors and a smooth finish.

KAIOU’s Dual-System DTG Printer: A Game-Changer

The KAIOU DTG-006 introduces an advanced dual-system setup that significantly enhances productivity by combining garment printing and a thickener (pre-treatment) system. Pre-treatment is typically a separate step that requires manual intervention or additional machines, but with KAIOU's dual-system printer, pre-treatment and printing happen in one continuous process. This integration simplifies operations, saves time, and ensures consistency.

Key Features of the KAIOU DTG-006:

Print Head Configuration: The DTG-006 uses the Epson i3200 series print heads for both color printing and pre-treatment. It includes four i3200 print heads for garment printing and two additional i3200 print heads dedicated to applying the pre-treatment solution.

Speed: The DTG-006 can print 100 white garments per hour and 65 black garments per hour, making it one of the fastest DTG printers in the market.

Print Size: A standard print area of 41x51 cm allows for large, intricate designs on garments, whether it's a full-front design or a more intricate pattern.

Efficiency: By combining printing and pre-treatment in a single system, the DTG-006 reduces labor and operational steps, leading to increased throughput and reduced human error.

Printhead Performance

The performance of any DTG printer heavily depends on the type of printhead it employs. The Epson i3200 series, used in the KAIOU DTG printers, is known for its reliability, speed, and precision. This printhead features Micro Piezo technology, which delivers ultra-fine ink droplets, ensuring sharp details and smooth color transitions.

Resolution: The i3200 printheads offer resolutions up to 1200 dpi, allowing for photo-quality prints and intricate designs.

Durability: Epson printheads are robust and durable, designed to handle large-scale production without frequent replacements.

Ink Compatibility: These printheads are optimized for water-based textile inks, which are eco-friendly and safe for direct contact with skin.

When integrated into the dual-system design, the printheads serve dual functions: one set for printing and the other for applying pre-treatment solutions. This ensures that every garment is perfectly pre-treated before the ink is applied, leading to better adhesion, color vibrancy, and durability.

Operating Process of KAIOU’s Dual-System DTG Printer

Garment Loading: Place the garment onto the machine's platen, which holds the fabric in place.

Pre-Treatment: The machine automatically applies a thin layer of pre-treatment solution using the dedicated pre-treatment printhead system. This step is crucial for dark fabrics, as it allows white ink to stand out vividly.

Printing: After pre-treatment, the machine starts the printing process. The fabric passes through the printing station where the design is applied directly to the garment using the i3200 print heads.

Drying: Once printed, the garment may require heat curing to set the ink and improve durability. This step can be integrated with a heat press or conveyor dryer depending on the production setup.

Finishing: The garment is ready for inspection, folding, and packaging.

This streamlined process means that fewer hands touch the garment, reducing the risk of contamination, smudges, or errors.

ROI and Market Prospects for Custom Apparel

Investing in a KAIOU DTG-006 dual-system printer offers a strong return on investment (ROI), particularly for businesses that focus on customization and short-run production. The global market for personalized and custom apparel is expanding rapidly, driven by the rise of e-commerce platforms like Amazon, Etsy, and Shopify, where individuals and brands sell custom-designed products directly to consumers. Additionally, retail chains and fashion labels are increasingly adopting DTG technology to meet the growing demand for on-demand printing and faster product turnarounds.

Lower Operational Costs: The dual-system reduces the need for multiple machines or operators, translating into savings on both labor and equipment.

Faster Production Times: With pre-treatment and printing occurring in one streamlined process, orders can be fulfilled more quickly, allowing businesses to handle high-volume orders or last-minute requests.

Scalability: The printer's high throughput—up to 100 white garments per hour—makes it ideal for scaling operations without significantly increasing labor costs or space requirements.

Customization Market Growth: The custom apparel market, including businesses selling on platforms like Amazon, eBay, and Etsy, is booming. Consumers are looking for unique clothing that reflects their personality, making DTG printing a key enabler of this trend.

Reduced Waste: Unlike traditional printing methods that require large minimum order quantities, DTG allows for cost-effective single-unit production, reducing overproduction and inventory waste.

Advantages of KAIOU’s Dual-System DTG Printer

Streamlined Workflow: The dual-system DTG printer integrates both pre-treatment and printing into a single machine. This reduces the need for multiple machines and operators, making the process more efficient and less time-consuming.

Consistent Quality: The automated pre-treatment ensures a consistent application of the solution, which is essential for achieving high-quality prints, especially on dark fabrics where white ink is used. This consistency reduces the number of rejects and reprints due to poor pre-treatment.

Increased Productivity: The dual-system setup allows for continuous operation without needing to transfer garments between machines. This increases the overall production rate, helping businesses meet tight deadlines and high-demand periods.

Reduced Labor Costs: By automating the pre-treatment and printing process, the dual-system printer reduces the need for skilled operators. A single operator can manage the entire process, lowering labor costs and reducing the risk of human error.

Space Efficiency: Instead of using separate machines for pre-treatment and printing, the dual-system printer combines both functions in one unit. This is particularly advantageous for businesses with limited floor space.

Improved Turnaround Time: The reduced handling of garments and the streamlined workflow result in faster production times. Businesses can fulfill orders more quickly, which is particularly valuable in the fast-paced world of e-commerce and custom fashion.

Automation and Optimization: KAIOU’s dual-system printer comes with optimized software that automatically adjusts the amount of pre-treatment solution and ink based on the fabric type. This automation improves print quality and reduces the need for manual adjustments.

KAIOU DTG-006 dual-system printer represents a significant leap forward in DTG technology, offering unmatched productivity, quality, and efficiency. Its dual-system design simplifies the printing process by integrating pre-treatment and printing into one seamless operation. This innovation not only reduces operational costs and labor requirements but also ensures consistent, high-quality prints. With the growing demand for custom apparel in both e-commerce and retail, investing in a KAIOU DTG printer is a strategic decision for businesses looking to capitalize on this trend and maximize their ROI.

English

English  Portuguese

Portuguese  Spanish

Spanish  Italian

Italian  Turkish

Turkish  French

French  German

German