DTF powder shaker machine

| Product Model | Digital printing powder machine H650 |

| Advailable width | 0-600mm |

| Application | Nylon, chemical fiber, cotton,leather, swimsuit, diving suit,PVC, EVA .etc |

| Powder control | Powder shack control, Powder and amount control, etc |

| Heat and dry function | Front heat plate ,dry fixation, cold fans function |

| Media transmission | NEW belt type |

| Take up function | Automatic inductive |

| Size | Machine size 1985*1090*1080, Package size1930*1120*1136mm |

| Weight | G.W: 260kg N.W: 180kg |

- Description

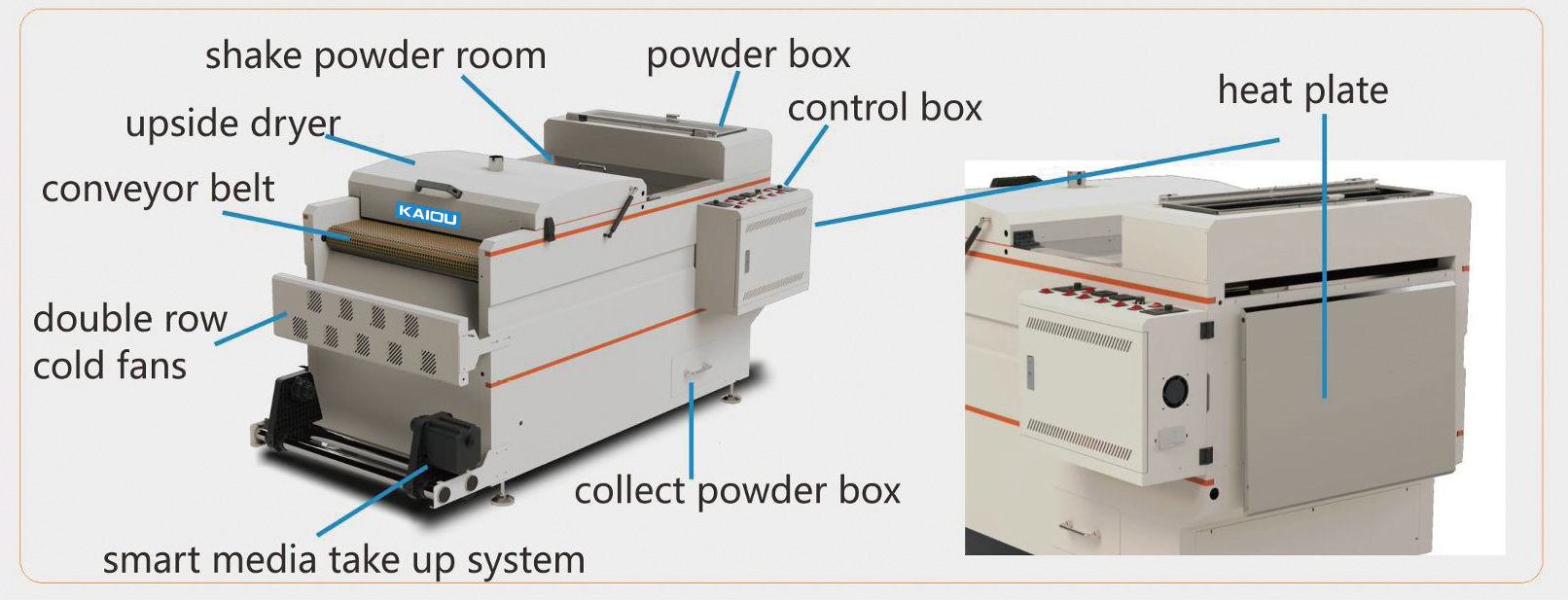

Introducing KAIOU’s Digital Printing Powder Machine H650, a powerful addition to enhance your DTF (Direct to Film) printing workflow. Designed with an elegant white body, the H650 stands out with both style and functionality. It is built to work seamlessly with KAIOU DTF printers, providing consistent and precise powder application for top-tier printing results.

Key Features of the H650 Powder Machine

Advailable Width

The KAIOU H650 accommodates media with a width of up to 600mm, making it versatile for various printing needs. Whether you are working on small or large projects, the H650 ensures perfect powder application across different sizes, enhancing the print quality and durability.

Application

This powder machine is suitable for a wide range of fabrics and materials, including nylon, chemical fiber, cotton, leather, swimsuit, diving suit, PVC, EVA, and more. Its versatility makes it an ideal choice for businesses looking to print on diverse substrates for customized apparel, accessories, and industrial items.

Powder Control

The H650 is equipped with a sophisticated powder control system that includes powder shack control, powder amount control, and precise distribution settings. This ensures that the powder is applied uniformly and consistently, which is essential for creating durable, high-quality prints. The ability to control powder amounts means reduced waste, saving you material costs over time.

Heat and Dry Function

The machine's heat and dry function utilizes a front heat plate for fast, efficient drying and fixation. Additionally, a cold fan system is integrated to cool down the material after heat treatment, ensuring that the prints retain their quality and do not warp or distort during the process. This function improves the overall workflow by speeding up the drying process while preserving the print's vibrancy and detail.

Media Transmission

The H650 features a new belt-type media transmission system, which offers smoother and more stable media handling. This reduces the risk of jams or misalignments during printing, ensuring a consistent output and reducing production downtime.

Automatic Inductive Take-Up Function

One of the standout features of the H650 is its automatic inductive take-up system. This intelligent system ensures that the printed film is collected neatly and efficiently without manual intervention, improving workflow automation and increasing productivity. The automatic take-up function also ensures better handling of delicate prints, reducing the likelihood of smudges or damage.

Difference Between Belt-Type and Traditional Powder Machines

Compared to traditional powder machines, the H650’s belt-type media transmission system offers enhanced precision in handling materials, especially for high-volume production runs. Traditional machines may rely on rollers, which can sometimes cause alignment issues or uneven powder application. The belt system, by contrast, provides more stability and uniformity during the entire process, ensuring a higher quality output with fewer errors.

Moreover, the H650’s advanced powder control system is more sophisticated than what is typically found in ordinary powder machines, offering better fine-tuning options for different projects and reducing wastage. The automatic inductive take-up function also adds to the H650’s convenience, automating more of the process and reducing the need for constant manual oversight, unlike older models that require more manual input

KAIOU H650 Digital Printing Powder Machine is an advanced, efficient, and highly adaptable tool for businesses involved in DTF printing. With its broad material compatibility, enhanced powder control, efficient drying system, and automatic take-up features, the H650 ensures top-quality prints and a streamlined production process. If you’re looking to upgrade your printing setup for superior output, enhanced efficiency, and reduced manual intervention, the H650 is the perfect choice.

Contact us today to learn more about how the KAIOU H650 can fit into your production line and take advantage of our factory pricing and bulk order discounts!

English

English  Portuguese

Portuguese  Spanish

Spanish  Hungarian

Hungarian  Indonesian

Indonesian  Italian

Italian  Polish

Polish  Turkish

Turkish  Ukrainian

Ukrainian  Japanese

Japanese  French

French  German

German  Malay

Malay  Swedish

Swedish